| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

C&PS Lotsman+ L2 - 80 - Control & Protection Station "Lotsman+ L2"

- Series description

- Technical characteristics

- Downloads

- Related content

- Pumping EQUIPMENT

- Metallurgy, mining

- Food industry

- Firefighting

- Water intake

- Water supply

- Drainage

- Waste water

- Circulation

- Boiler water

- Water supply

- Water supply

- Circulation

- Boiler water

- Condensate removal

Function

C&PS «Lotsman+ L2» ensures the following design conditions:

- protection of three-phase induction motors:

- protection of electric motor against current overload/underload;

- protection of electric motor against phase loss, electrical imbalance or wrong phase sequence;

- protection of electric motor against increase/decrease of electrical line voltage;

- protection of electrical motor against body contact (ironwork fault);

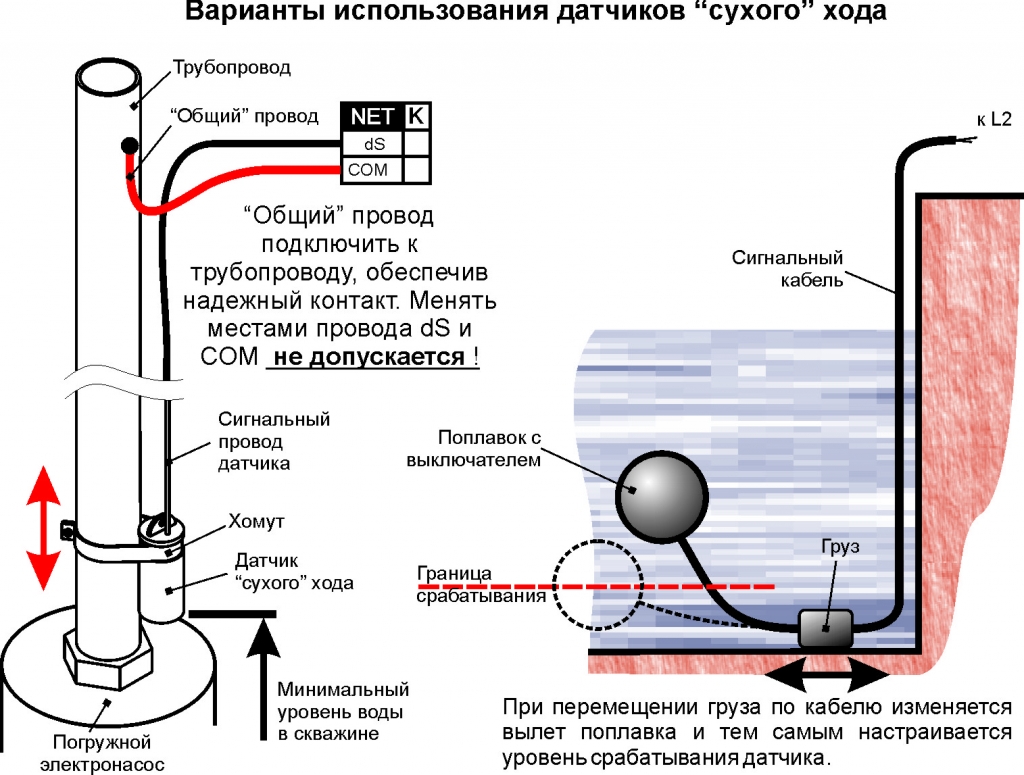

- protection of the electric motor and pump against “dry” running.

- automatic control over pumping units in the course of filling/discharging the liquids into the reservoirs – automatic maintaining of water level in the reservoirs;

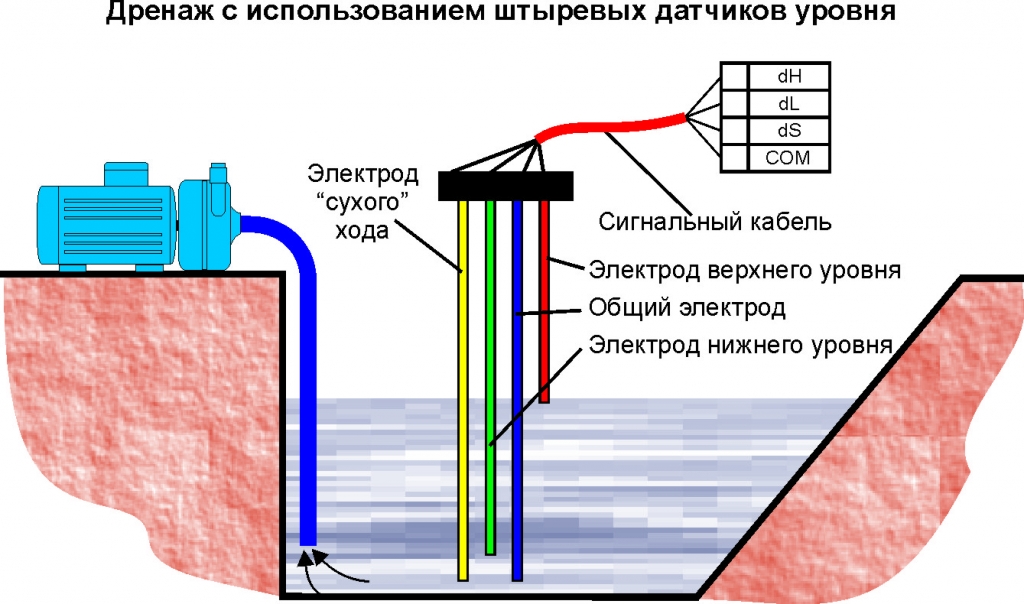

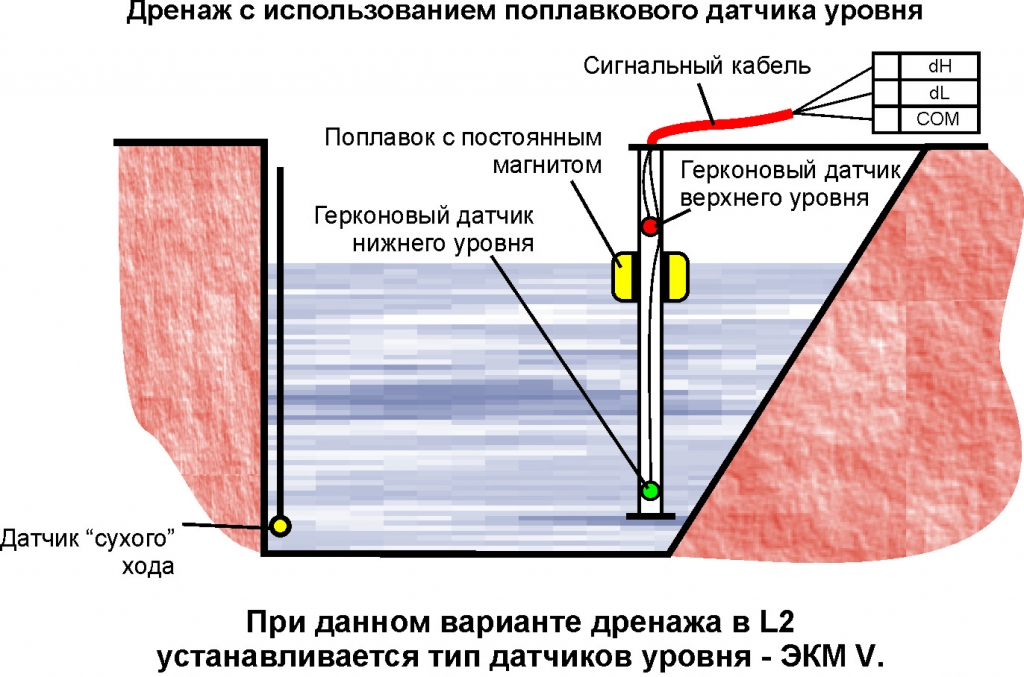

- automatic dewatering of drainage pits through the instrumentality of the level gauges (level indicators);

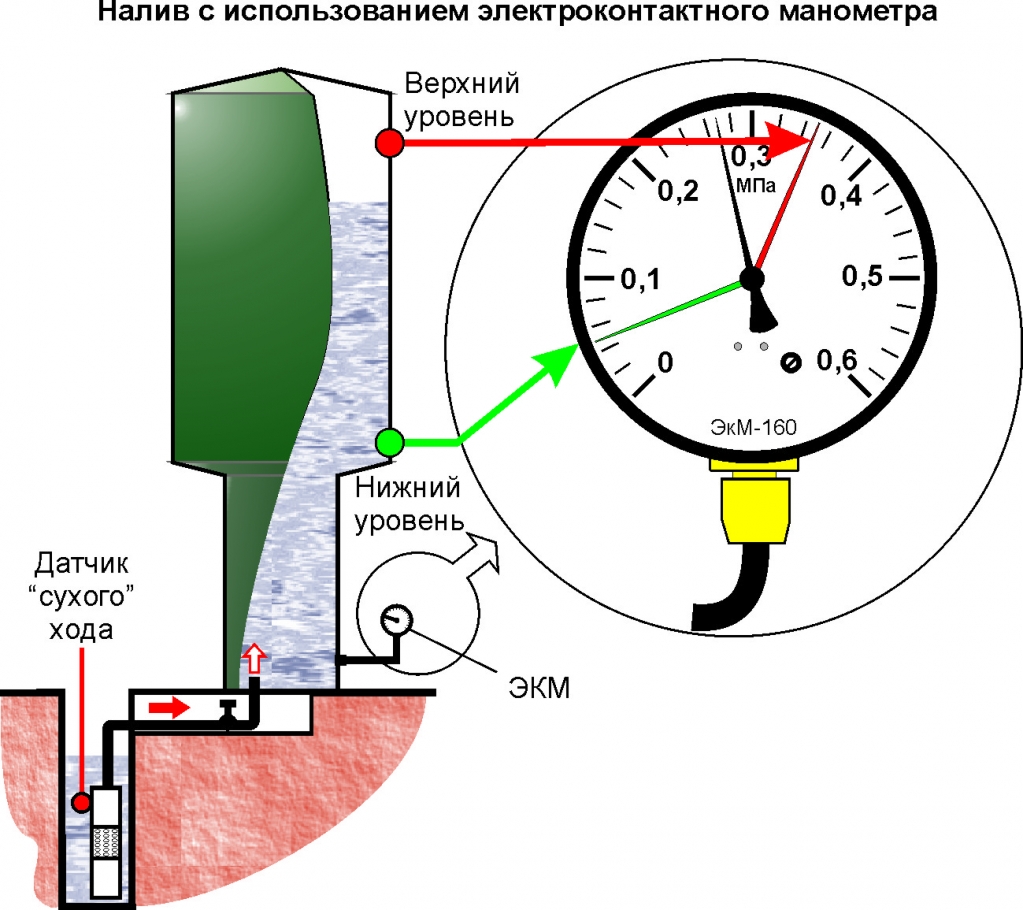

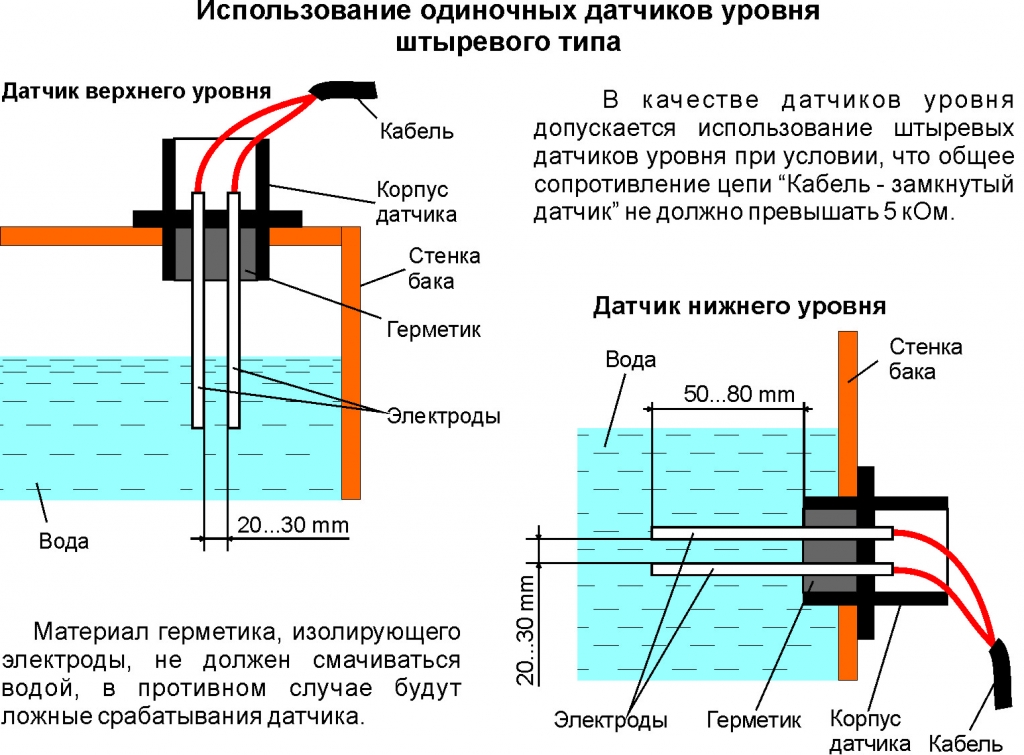

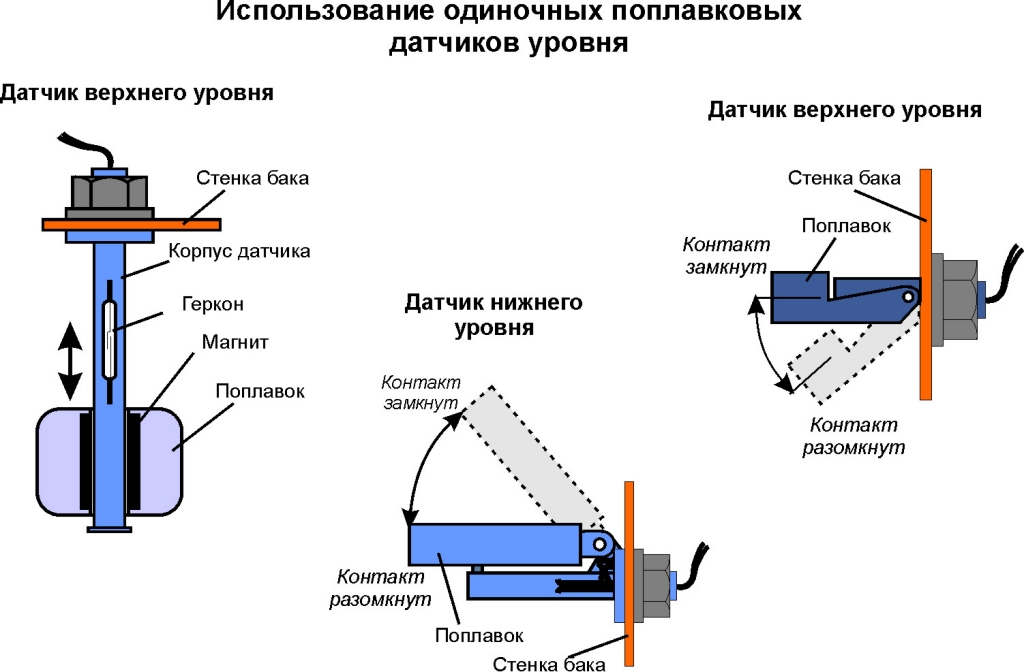

- the single sensors with “dry” contacts, electric contact-making manometres (ECM) of any version, float switches, conductometric sensing elements (electrode sensors) and others digital sensing elements – may be used in the capacity of level gauges;

- extended range of temperature and too high level of dust-and-moisture protection; this makes it possible to use the station on open air;

C&PS corresponds to climatic version U2 as per GOST15150-69. (U2 – denotes operation in unheated premises or under the shed at a temperature of ambient air from minus 40°С up to plus 40°С and high value of relative humidity of 80% without formation of the condensate.). level of protection of the C&PS against water and dust - IP 54 as per GOST 14254-96.

As far as the matter of protecting people against electrical shock is concerned, C&PS is related to the 1st class as per GOST 12.2.007.0 -75.

Design

Control and Protection station consists of the control board with removable assembling panel, within which provision is made for automatic circuit breaker, electromagnetic contactor, three terminal blocks (power blocks and signal blocks), current sensors (current transformers) and micro-controlling device for control and protection “L2" (hereinafter referred to as the МК).

Arranged on the door of the board is a transparent window for controlling the working status of the station.

The front panel of the MC is provided with the following control buttons: «START», «STOP», «PROGR.», «CHOICE», four-discharge light-emitting indicators and the LEDs indicating sensors' condition, modes of operation and emergency situations.

Figure:

- датчики тока – current sensors

- устройство управления и защиты L2 – control and protection device L2

- выключатель автоматический – automatic circuit breaker

- монтажная панель – assembling panel

- клеммный блок силовой – power terminal block

- контактор - contactor

- клеммный блок сигнальный – signaling terminal block

The operating principle of the C&PS is based on the processing the signals coming from the external sources to the MC, and on operating the electromagnetic contactor which is to switch on/off the electric motor.

Provision is made for two modes of operation: manual operation, when the startup/stoppage of the motor is carried out by pressing buttons “START”/“STOP”, or one of the automatic modes of operation, when the startup/stoppage of the electric motor is carried out via the signal (s) from the level (pressure) sensor (s).

Application

- to ensure automatic control, monitoring and protection of the submersible/centrifugal pumps which are used at the water services plants, within Housing and Utilities infrastructure;

- to ensure control and operation of the submersible/centrifugal pumps working within the systems of water supply/water removal of the industrial plants;

- for agriculture purposes, in order to control and protect submersible/centrifugal pumps which are used within the systems of watering of the farmlands;

- within the systems of pressure boosting of the residential and industrial using activities;

- for the purposes of heat and power engineering, in order to operate, control and protect the submersible/centrifugal pumps used within the systems of process water supply;

- automatic dewatering of the drainage pit by using the level gauges;

- at the industrial productions, in order to ensure control, operation and protection of the subassemblies and mechanisms, in which structure good use is made of the three-phase induction electric motors.

Features /Advantages

- easy adjustment of modes of operation and parameters of protection;

- possibility to make corrections in the station settings in the course of operation without stopping the station (for example, readjustment of protection currents);

- possibility to represent discrete signals indicating station operation just on the supervisory keyboard (dispatching desk);

- light-emitting signalling which serves to indicate automatic mode of operation, motor condition and level of liquid in the reservoir (by signals from the sensing elements);

- track of operating time and record keeping of number of the engine starts in order to perform well-timed technical maintenance;

- possibility of cascaded operation of several stations to suit one storage tank or main line;

- additional input «External control»: thus allowing to operate the station remotely;

- additional feed of the level gauges' circuits with alternating current: thus ensuring to reduce considerable the electrochemical corrosion of the electrode sensors and to prevent settling of water-dissolved salts;

- calculation of working values of the currents and voltages (TrueRMS) for every phase and their representation (displaying) on the light-emitting indicator;

- additional modes of operation (timers of launch delay, stop action, emergency shutdown and other timers);

- automatic restart of the motor after operating trouble or after loss of electric power supply of the station;

- galvanic isolation from the mains of all sensors' circuits within the microcontroller, thus excluding injury by current for the attending personnel;

- possibility to work with different current sensors, namely: sensors of Т03(Т-7) type and sensors with unifying current output of 5A (without modification of hardware and software);

- adjustment of the station does not require additional equipment and it is easy to be serviced by low-skilled personnel;

- low cost;

- it has been certified for use within the Customs Union.

Technical parameters

| Options | Values |

| Series | C&PS Lotsman+ L2 |

| Weight, kg | 11 |

Pump type key

For example C&PS Lotsman+ L2-25-IP54-U2 TU 3432-112-00217975-2011, where:

- C&PS - control and protection station

- Lotsman+ L2 – trade mark

- 25 – is the maximum working current of the electric motor to be connected up, А

- IP54 – degree of protection of enclosure as per GOST 14254-96

- U2 – climatic version and location category

Main specifications

|

Denomination |

Parameter |

|

Rated supply voltage, V / current frequency, Hz |

~380/50 |

|

Quantity of in-feeds, pcs. |

1 |

|

Tolerable deviation of the supply voltage fr om the rated value, % |

+10 - 15 |

|

Maximum current of the electric motor to be connected up, А (depending on the version) |

200 |

|

Range of temperature during operation, °С |

-40…+40 |

|

Degree of protection of enclosure as per GOST ГОСТ 14254-80 |

IP54 |

|

Inputs of electric power supply, electric motor and sensors |

in the bottom portion of the control cabinet |

|

Rind of climatic version |

U2 |

Input signals of the control cabinet

|

Denomination of the input signal |

Kind of signal |

|

Sensor of “dry” running |

~ 15V |

|

High-level indicator | |

|

Low-level indicator | |

|

«External» control |

Output signals of the control cabinet

|

Denomination of the output signal |

Characteristics |

|

Event (signal) to be adjusted by the User (it is chosen in the MC setup menu) |

Normally open/Normally closed contacts of relay ~250V, 1А |

C&PS ensures operation of the pump in the following modes of working:

- «Manual operation» - the pump motor is activated by buttons on the frontal panel of the controller;

- «Automatic operation» - control is effected by way of a signal coming from the pressure/level sensors.

In automatic mode of operation the C&PS ensures the following main functions:

- filling/discharge of the reservoirs according to signals coming from discrete level sensors of different type (electrode sensors, electric-contact manometers, float sensors and so on);

- filling/discharge of the reservoirs in response to a timer and in according to one of the level gauges (timer value from 1 up to 180 minutes);

- filling/discharge of the reservoirs according to the pressure relay;

- remote switching on/off of the station motor in response to an external control signal;

C&PS ensures protection in the following situations:

- «dry» running (when use is made of the corresponding sensor (s));

- overload of the motor - – to be adjusted by the User within the range of 1…300 А;

- underload of the motor (protection against «dry» running without additional sensor) – to be adjusted by the User within the range of 0,5…299 А;

- wrong sequence or absence of input phases (to be checked during switching-on);

- too high or too low supply voltage –to be adjusted by the User within the range of 180…245 V;

- phase loss/electrical imbalance;

- failure action of the level gauges (level detectors) (under automatic operation conditions);

- too low insulation resistance of the electric motor – less than 15 кOhm.

Manual mode of operation

Manual mode of operation is intended for local control of the motor in the course of assembly and service activities. The proper motor switching in/off is effected only by depressing the buttons «Start»/«Stop», arranged on the frontal panel of the MC. Transition to the manual mode of operation takes place when the Operator changes the value of parameter 1 of the MC setup menu. With the unit being operated manually, all the protective gears (protections) are actuated but with the exception for control of correct actuation of the level indicators. When the protective gear is actuated the motor is to switch off and the blinking inscription about emergency situation together with the sound signal is displayed before the operator intervention.Timer clock of duration of work and the switch on/ switch off time timers are not used.

Automatic mode of operation according to the level gauges

Under automatic operation conditions the pump motor is automatically switched on/off according to the discrete pressure/level sensors. Depending on the station function that is to be chosen by the User it is possible to maintain automatically the water level in the reservoir or to drain the drainage pits.

«Filling» Control Function

When the liquid column is lowered below the low-level indicator, the supply mains and motor are checked for condition and the signal of the sensors is verified for correctness. Thereupon the actuation of the pump motor takes place. In the course of filling process the control of currents and voltages is constantly carried out, those values are to be within the set limits. If the current and voltage values go beyond the target values' range during the prescribed time period, the electric motor is subject to emergency shutdown. In such a case the indicator will display the code of the offered error and the time up to the next following launch of the motor. Additionally in the course of operation the status of the input “External control” and the condition of the “dry” run sensor are to be verified. When the reservoir is filled up till the upper level, the motor is switched off and the MC (microcontroller) is moved to the drainage waiting mode.

Under automatic operation conditions the status of the level gauges' contacts is always controlled..

As the problem connected with wrong functioning of the sensor contacts appears (for example, the high-level indicator is actuated prior to the low-level indicator), the level LEDs start flashing and in 2 minutes the protective gear is activated. The motor is switched off and the blinking emergency code is displayed. The error is cleared just after regeneration of signals coming from the sensors (indicators).

Some additional functions are available during automatic operation, namely: emergency shutdown timer and on and off delay-make timer.

The emergency shutdown timer is designed to exclude the overfilling due to fault of one of the level gauges (for example, the high-level indicators at the water tower are frequently frozen). The task of the timer – to de-energize the motor on expiration of time period prescribed in the setup menu (in minutes), if the high-level indicator did not come into action. The timer is initiated together with the motor actuation during filling process and it is reset to zero when the motor is switched off. If the level gauge operates prior to the timer (with respect to time), so the timer is stopped up to the next following motor activation. After timer-clock response and on expiration of restart time after emergencies, the operation of the station is to be continued as per normal, the Microcontroller looks forward to lowering of the liquid level.

On & Off delay-make timers make it possible to ignore false level signals under possible water hammer effects on the long lines, which are involved just after motor switching in/off. The start-up command or the stop command of the motor will be executed only after stabilization of the pressure jump and stable condition of the sensor contacts during time period predetermined by the User. In addition, one should use delay timers in order to organize the group (cascade) mode of operation for several pumps just to suit one storage tank or drainage tank with common level gauges. Switch on/ switch off time of every station from the group is adjusted in dependence to operation conditions for a time period up to 180 seconds.

«Drainage» Control Function

Operation of the station under drainage conditions is identical to operation under filling-up conditions with the exception of reverse sequence of motor switching in/off when the liquid level is changed. When the liquid comes up to the upper level, the motor is just actuated. When the minimum level has been reached, the motor is stopped, in such a case the station will be looking forward to filling-up of the reservoir up to the upper level. Similar to above-mentioned filling-up function, it is possible to use the following functions, namely: switch on/switch off delay and emergency shutdown function as well.

As far as the “drainage” control function is considered, bear in mind that the launch time delay and the shutdown delay functions are in analogy with the station function during “filling process”, but the timer of emergency shutdown is activated jointly with the motor and is cleared when the lower level is reached.

Automatic mode of operation according to the timer-clock and the upper (lower) level indicators.

The said mode of operation is provided for such conditions when the installation of the high-level sensor (indicator) is not really possible (for example, the high-level sensors which are used at the water towers are to be covered with ice during hard frosts and as a result they become non-operative), and the electric-contact manometer has difficulty in use for some reason. In this case only one level indicator is to be installed; after its triggering the filling-up/drainage of the reservoir is effected during time lim it required for the purpose of filling and draining. The high-level sensor (indicator) is not used during automatic mode of operation. The filling function or drainage function is to be chosen in the setup menu of the microcontroller (MC). In the course of filling-up process the good use is made of the low-level sensor input, during drainage – the input of high-level sensor is brought into operation.

In the process of filling

If the sensor is found in open position, it means that the liquid is not present in the reservoir, so the pump motor starts working for a time ranging from 1 up to 180 minutes (time to be changed by the User in the setup menu). The time for filling a specific tank is selected by way of trials in hand-operated regime. When the time of filling is expired the MC will look forward to opening operation of the low-level indicator and then it will repeat over again the cycles of filling.

In the process of drainage

If the sensor is in closed condition, it means that reservoir has been filled up, so the motor starts working for a time ranging from 1 up to 180 minutes. Time required for draining the certain reservoir is chosen manually by trial. When the time of bleeding (draining) is expired, the MC will look forward to closing operation of the low-level sensor, иand then it will repeat over again the cycles of drainage.

As in all other modes of operation, the check-up of all applied protective parameters is carried out just before the start and in the course of the electric motor operation.

Remote discrete control over motor operation

Remote control is possible with the help of the input “External control” of the station. The said input must be enabled in the setup menu of the MC. Under automatic operation conditions the closure of the said input admits operation of the station in this mode of functioning, the opening (breaking) of the said input – forbids the operation. The motor is to be switched on just while the level gauges will operate with positive action in accordance with applied duty cycle and function. Restart after emergency condition will take place after the expiry of the prescribed hold-up time.

During manual operation at closing of the input, the electric motor is energized immediately, at opening of the input – it is de-energized. After actuation of the protective gear the motor is to be switched off and the blinking code of emergency will be kept on the indicator. The alarm clearance and restart in case of enabled input «External control» - the opening of the said input or the depressing the «Stop» button of the MC. The emergency condition will be cleared and, in dependence to input status, the motor will be switched in/off.

In the time of activated «External control” input, the buttons «Start» and «Stop» of the Microcontroller are blocked.

Distance transmission of operative signals

For distance transmission of the signals to the dispatcher desk or CPCS (computerized process control system) provision is made in the station for electromagnetic relay K2 of the controller with double-throw contact.

The closure of the relay contacts takes place in dependence to selected condition within special item of the MC setup menu. Available are the following variants of relay actuation:

- operation of the station;

- emergencies of the station;

- switched in/off the motor;

- input condition «External control»;

- input condition «High-level indicator»;

- input condition «Low-level indicator»;

- input condition «Sensor of “dry” running».

In case of necessity, the signal «Switched on/off motor» may be obtained by using additional NО-contact (a-contact) which is accommodated within the electric contactor.

To be more familiar with the operation of the station refer to the documents «L2 Programming Manual», «Operation manual Lotsman+ L2».

The use of different types of level sensors :

|  |

|  |

|  |

|

|

|

|

|

|

|

|

Instruction manual :

All technical documentation in the Russian version of the site »

Certificates, permits :

All certificates, permits in the Russian version of the site »

Linked products :

News :

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851