| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

D125-250A - DeLium Horizontal Double-Entry Pumps

- Series description

- Technical characteristics

- Downloads

- Related content

- Double-suction

- Nuclear power

- Chemical processing

- Metallurgy, mining

- Firefighting

- Water intake

- Water supply

- Water injection

- Midstream

- Downstream and petrochemistry

- Water supply

- Water supply

- Chemically active

- Clear water

- Brine water

- Sea water

- Hot water

- rock-oil

- oil

- benzine

- kerosin

- diesel fuel

- water + petroleum products

Function

Centrifugal double-entry pumps of Delium type and electric pump units on their base designed for pumping:

- Water and nontoxic liquids having similar properties to water in viscosity and chemical activity, at a density of up to 1100kg/m3, viscosity of up to 60*10-6 m2/s (60сSt), temperature ranging from 274К up to 378К (from +1 up to +105°С), and with solid particles not exceeding 0,2% by weight, with no particles larger than 0,2mm and no particles with microhardness more than 6,5 GPа (650kgf/mm2).

- Oil and petroleum products having a viscosity of up to 100*10-6m2/s (100сSt), at a temperature from 274К up to 378К (from +1 up to +105°С), containing not more than 0,2% by weight of solid particles, with no particles larger than 4mm and no particles with microhardness more than 6,5 GPа (650kgf/mm2).

- Sea water, strata water and other chemically active liquids with hydrogen index рН=1...11 and with mechanical admixtures up to 0,2% by weight, with a size not more than 0,2 mm and microhardness not exceeding 6,5 GPa (650kgf/mm2), at a temperature ranging from 274К up to 378К (from +1 up to +105°С).

It is possible to fabricate the pumps (units) for handling liquids with a temperature of up to +120°С. Pumps and units are manufactured in climatic version and location category UXL 3.1, U2 and Т2 as per GOST 15150-69. Pumps and units are designed for the regions with seismic activity up to grade 7 for the cast-iron make and up to grade 9 for steel make in conformity with MSK-64 scale.

Pumps and units are made in accordance with general safety requirements as per GOST 31839-2012. The units furnished with pumps having a modification index «Е» and equipped with explosion –proof electric motors may be used in explosion-and-fire hazard productions, area class 1 and 2 as per GOST 30852.9-2002.

Design

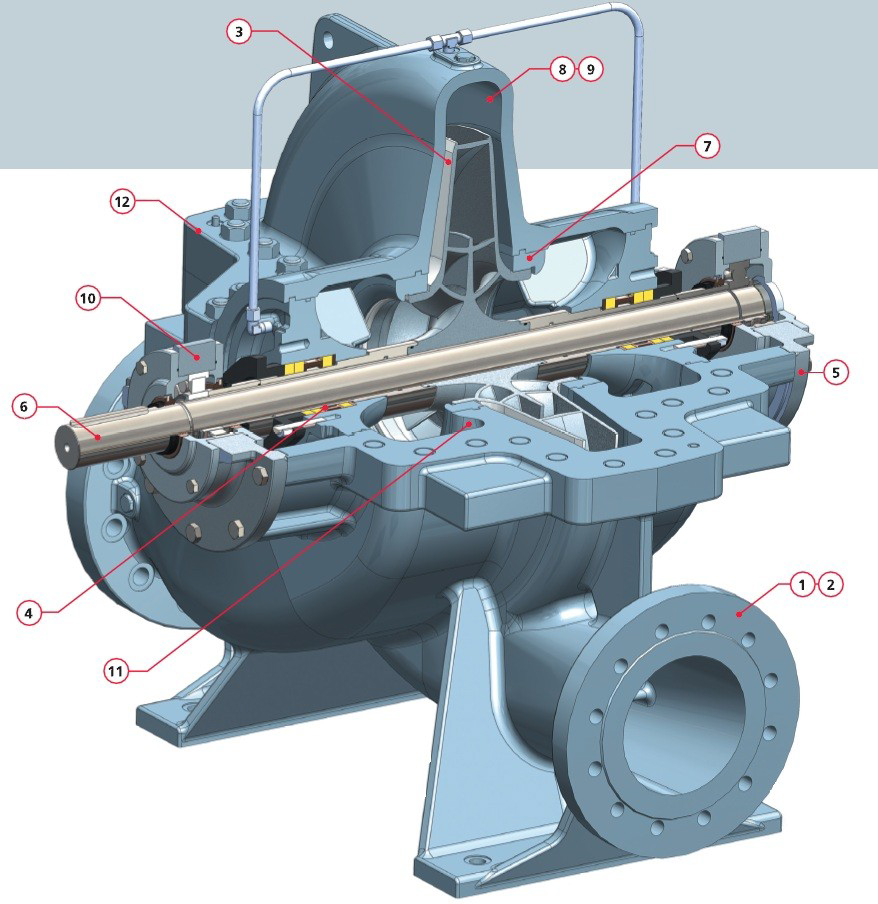

Pump of Delium type - is centrifugal double-entry horizontal single-stage machine with double-sided semivolute delivery of liquid to the impeller of double-entry and with volute discharge. It is possible to fabricate the unit of vertical modification.

The principle of operation of the pump consists in transformation of mechanical power of the drive into the hydraulic energy of the liquid due to hydrodynamic influence of the blade system of the impeller, inlet and outlet.

Electric pump unit consists of the pump and driving motor, mounted on common welded foundation frame and interconnected by coupling.

The casing of the pump is an iron casting or steel casting, which has a joint in the horizontal plane passing through the axis of the rotor. The suction and delivery branch pipes of the pump are positioned in lower portion of the casing and are directed in different directions, owing to which it is possible to disassemble and repair the pump without disconnecting pipelines and removing the electric motor. Mounting dimensions of the flanges of the suction and delivery pipelines are made as per GOST 12815-80 (at the Customer's request it is admissible to produce the flange version as per GOST 12815-80).

The rotor of the pump is put in rotation by electric motor through the coupling. The accuracy class of the rotor balancing G 6,3 in conformity with GOST ISO 1940-1-2007.

The radial ball bearings and radial roller bearings, which are lubricated by consistent grease, serve as rotor supports for the horizontal pumps. For the vertical pumps provision is made for the radial-thrust double-row ball bearing which is lubricated by consistent grease and the plain bearing lubricated by pumped liquid.

The sense of rotation of the rotor is right-handed (clockwise), if viewed from the drive end. At the Customer's request it is possible to fabricate the pump with left-handed rotation of the rotor (counterclockwise).

Impeller – is of double-entry type; it allows to place the axial forces in equilibrium. The residual axial forces are taken by ball bearings.

To prevent leakage of liquid along the shaft provision is made in the pump casing for stuffing box seals or single end-face seals. When handling liquids with a temperature of up plus 60°С the water lock of the gland is carried out by supplying liquid to the gland ring through the crossover pipe. Delivery of barrier and cooling liquid to the zone of the gland seal at a temperature of liquid being pumped above 333К (plus 60°С) is effected from the external source.

To transmit the torque from the electric motor shaft to the pump shaft use is made of the couplings with rubber-bushed studs.

At the Customer's request the unit may be completed by semi-rigid plate couplings for the corresponding moments. The coupling are provided with the guard.

The frame of the unit is a welded construction made of rolled iron. The unit on the frame is attached to the foundation with the help of foundation (anchor bolts).

Application

- Oil and gas industries

- Nuclear and Thermal power engineering

- Water supply and Utilities

- Metallurgy industry and mines

- Chemical industry

- General industry

- Agriculture

- Pulp and paper industry

- Food industry

- Sea fleet and inland navigation fleet

Features /Advantages

Design features:

1. Suction and delivery branch pipes are in line

2. Dimensions of the flanges are made as per DIN/ANSI/ISO.

The dimensions of the chambers of the end-face seals correspond to API 682 in order to accommodate seals of different manufacturers.

The construction design of the pump was worked out with due consideration of possible usage and operation in the regions having a seismicity of up to grade 9 earthquake as per MSK-64.

Большой выбор материальных исполнений обеспечивает возможность применения насосов для всех отраслей промышленности.

В качестве привода могут быть использованы электродвигатель, бензиновый/дизельный двигатель, турбина.

Превосходная всасывающая способность, низкий NPSH.

Low cost of maintenance services:

3. High level of unification of the main subassemblies for different standard sizes considerably reduces the cost of the maintenance.

4. The gland or single/double end-face seals are used in the capacity of shaft seals. The pumps for handling liquids with solid inclusions are provided with hydro cyclone.

5. The bearings may be provided with consistent grease or with lubricant in the oil bath. For the second variant provision is made for the cooling system. The service life of the bearings is not below 100000 hours.

Reliability:

6. The shaft is completely isolated from the liquid being handled.

7. Use of wear-resistant materials for the rings of the groove seals. Modifications with replaceable rings on the impeller.

8. Modifications with hydrophobic coating allow to increase the efficiency and to reduce the wear and erosion.

9. Two-coil spiral within the casing reduces the radial thrust onto the shaft.

10. Modifications with enforced bearings in order to increase the reliability during operation with severe loads under heavy conditions.

Efficiency:

11. The pumps were designed by 3D modeling. The flow passage was designed with use of state-of-the-art methods of the computational fluid dynamics in order to achieve maximum efficiency.

12. The use of two interchangeable impellers at least allows to match the pumps for any requirements.

Narrowed dimension between the bearings and the optimized hydraulics reduce the cost of the pump life cycle.

Vibration sensors and temperature sensing elements may be used/have been installed in the bearing bodies.

Easy of installation/operation:

12. Self-installing cover of the pump casing considerably simplifies the mounting.

Pumps may be supplied not only on the common frame with electric motors, but also on the separated frame.

The pumps may be used for horizontal installation and alike for the vertical installation. Vertical installation is regarded as the standard option.

Technical parameters

| Options | Values |

| Series | DeLium |

| Flow (nomin.), m³/h | 288 |

| Head, m | 16 |

| Pump power input (max.), kW | 17 |

| Rotation speed, rpm | 1450 |

| Rotation speed, c˜¹ | 24.2 |

| Pump efficiency,% | 86 |

| Admissible positive suction head, m, max | 1.6 |

Pump type key

For example: DV 200-660-A-b-S/S-t-Е-UXL 3.1 ТU3631-426-00217975-2014 , where :

- D - Delium – is pump series

- V – denotes position of the shaft: V – vertical position, without designation – horizontal one

- 200 – nominal diameter of the outlet branch pipe, mm

- 660 – nominal diameter of the impeller, mm

- А – rotor version

- b – turning of the impeller: without designation – main impeller, a,b – index of impeller turning

- S/S – version according to the casing/impeller materials:

without designation – Grey cast iron / Grey cast iron

SH/CH – Cast iron with spherical graphite / Grey cast iron

S/S - Steel / Steel

CH/B – Grey cast iron / Bronze

N/B – Stainless steel / Bronze

N/N – Stainless steel / Stainless steel

D/D – Duplex steel / Duplex steel - t - sealing of the shaft:

without designation – stuffing box seal

t – single end-face seal

ts – end-face seal with an auxiliary one

tt – double end-face seal (at the Customer's request) - Е – denotes pump (unit) version indicating to possible use of the machine in explosion-and-fire hazard premises

- UXL 3.1 – climatic version and location category (U2, Т2)

Instruction manual :

All technical documentation in the Russian version of the site »

Certificates, permits :

All certificates, permits in the Russian version of the site »

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851