| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

Test capabilities

In addition to full-scale manufacturing facilities the JSC HMS Livgidromash is in possession of experimental facilities and test capabilities, which are made of different certified laboratories, unique test benches, prototype production shops and work shops of limited edition (by small batches) of equipment.

Test facilities of JSC HMS Livgidromash is constantly upgraded and modernized: thus it makes possible to maintain up-to-dateness, business demand, marketability (competitive performance) and top quality of our pump-relating products.

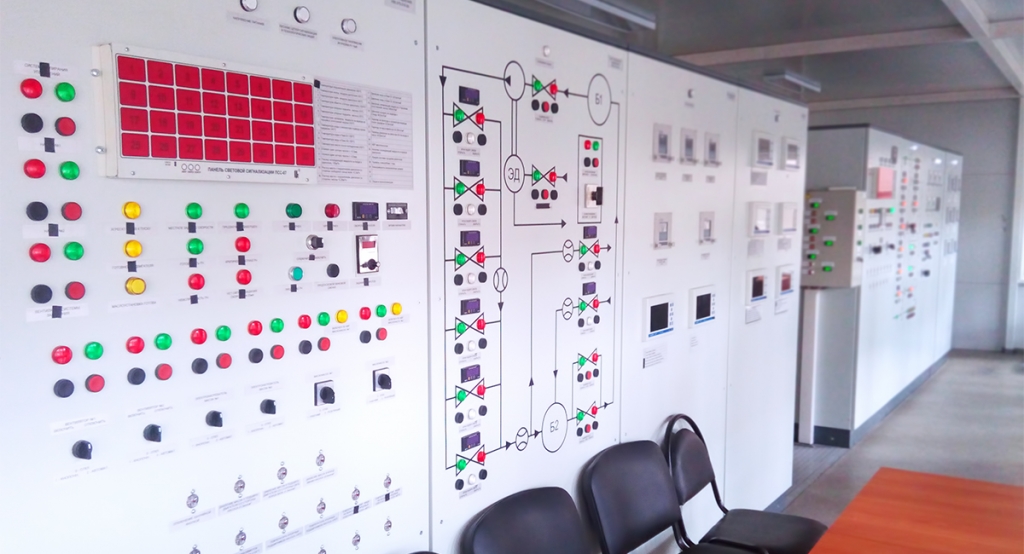

Test operations center

At the JSC HMS Livgidromash all the produced pumps and electric pump units are subject to control and tests for the purpose of checking the conformity of quality levels with the requirements of standards, Specifications and agreements, test programs and procedures, as stated in relevant technical papers for the products.

Test operations center of the JSC HMS Livgidromash has a long-term operational experience in performance of preliminary (initial) trials, acceptance testing, state acceptance procedures, qualification inspections, approval tests, sampling & routine testing of manufactured pumps and electric pump units on their base.

The tests are carried out by competent, highly-skilled specialists just at the certified test equipment. In total there are more than 100 test benches at the enterprise, intended for carrying out all kinds of tests.

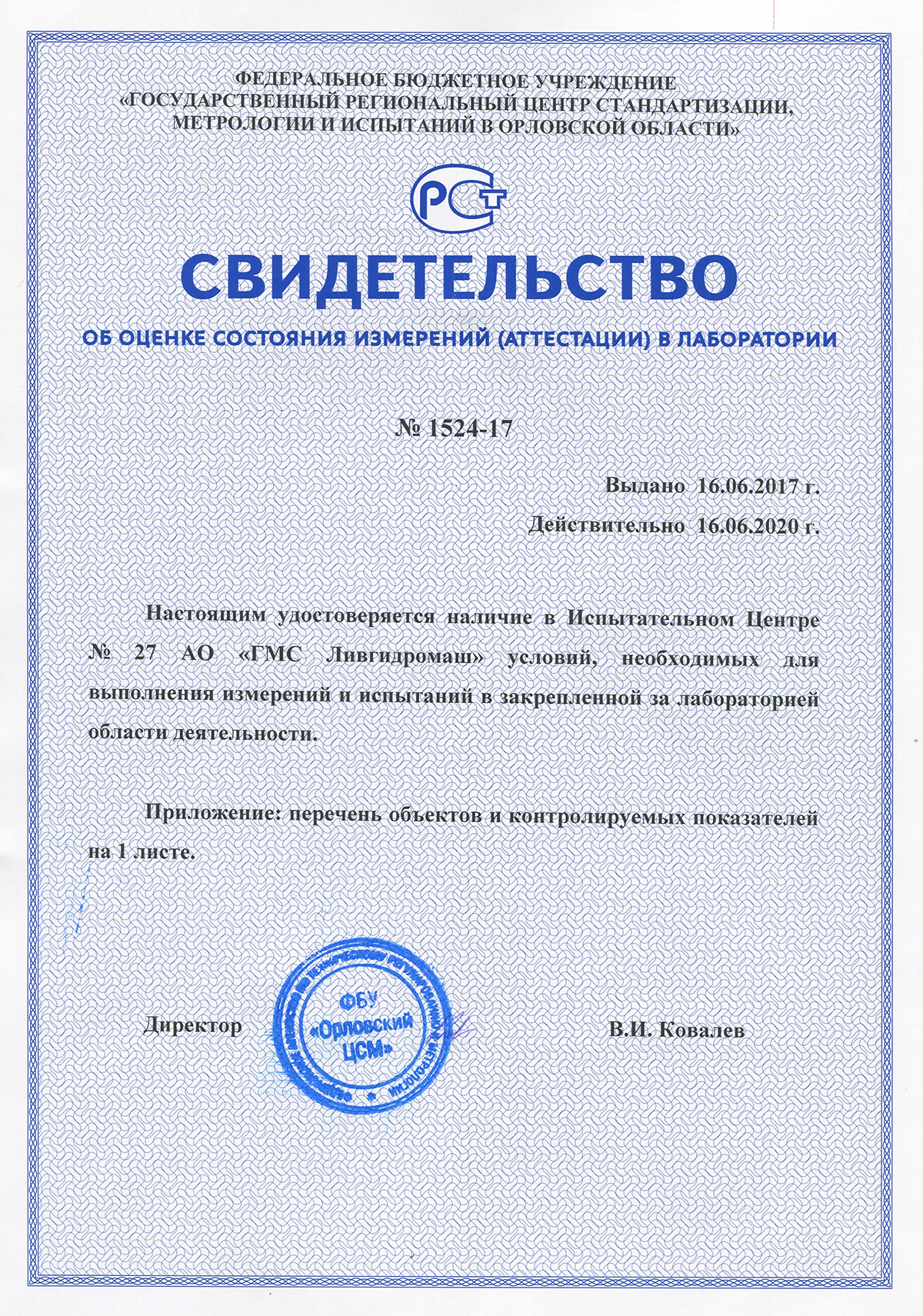

Test operations center of JSC HMS Livgidromash was attested by Federal State Institution «State Regional Center of Standardization, Metrology and Testing in the Orel region, accredited by state-base atomic energy corporation ”Rosatom”.

|

|

|

The test operations center has possibilities to carry out trials of pump-related products with the following parameters: capacity of up to 16000 m3/h, head of up to 630 m, power of up to 12500 кW, overall dimensions LхW m 13,5 х 5 and mass of up to 32 000 kg.

The said test operations center of JSC HMS Livgidromash is improved and modernized on a constant base. More than 10 all-new modern test benches were acquired, manufactured and placed into production over the last five years.

Central Factory laboratory

Central factory laboratory of JSC HMS Livgidromash gained knowledge of half a century and was attested by federal state regional center on standardization, metrology and test performance in Orel region, the staff members of Central factory laboratory were attested in JSC NIKIMT Atomstroy, t. Moscow, on destructive and non-destructive testing methods.

The central factory laboratory consists of 6 laboratories; each laboratory is to carry out necessary trials and checks by using different methods: namely, incoming inspections, control during current production stages, control of materials and final goods inspections in conformity with state and international standards.

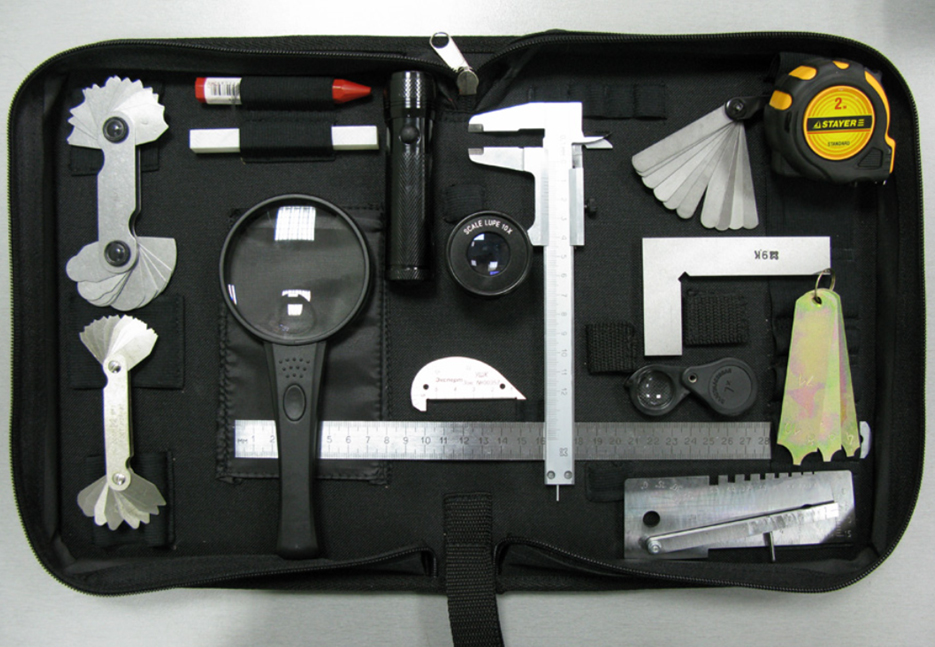

The non-destructive testing laboratory attested by the JSC NPI CNIITMASH performs visual inspection control, liquid penetrant testing, ultrasonic and electric controls. For the purpose of carrying out ultrasonic checks the laboratory is equipped with flaw detectors including phased array ultrasonics; the electrical technique is put in execution by defectoscopes in order to control uniformity of paint-and-lacquer coatings, polymer coats, epoxy finish, bitumen insulating covers of the gas- and pipelines, tanks and reservoirs and other metal structures.

|

|

|

| Set for visual inspection control and dimensional check | Set for liquid penetrant testing | Ultrasonc defectoscope on phased array |

The laboratory of chemical analysis carries out definitions of chemical composition of the casting products, non-ferrous metals and alloys, ferrous-based alloys, electrolytes, water solutions, and definitions of ferritic phase content and many other tests.

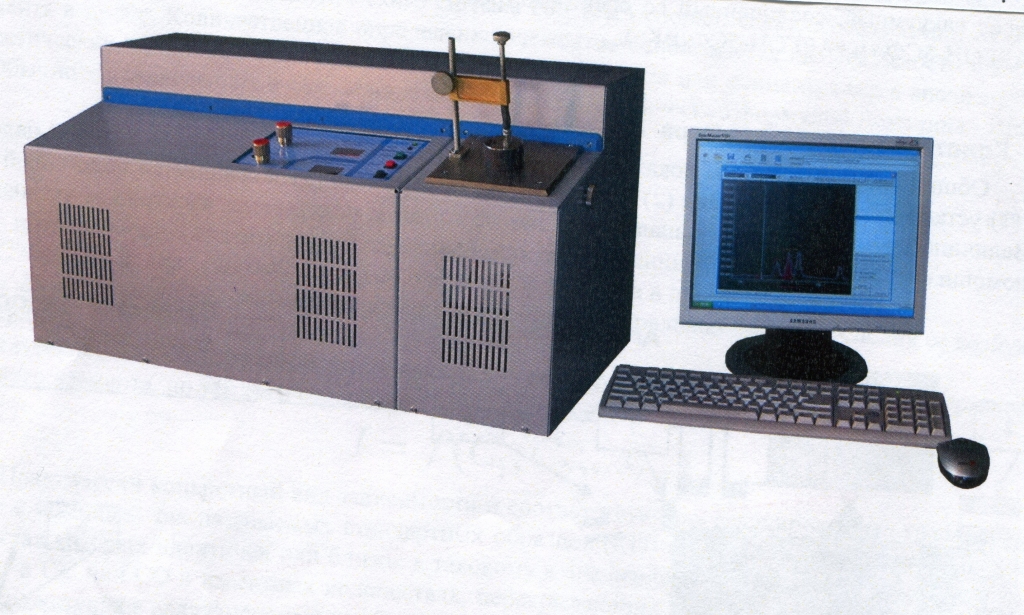

Mechanical laboratory is equipped with state-of-the-art basic and auxiliary testing equipment together with software support and analytical procurement.

|

|

|

| Tensile testing machine «Inspekt 250» | Universal hardness testing КВ-3000 | Tensile-testing machine ВР U2DLC |

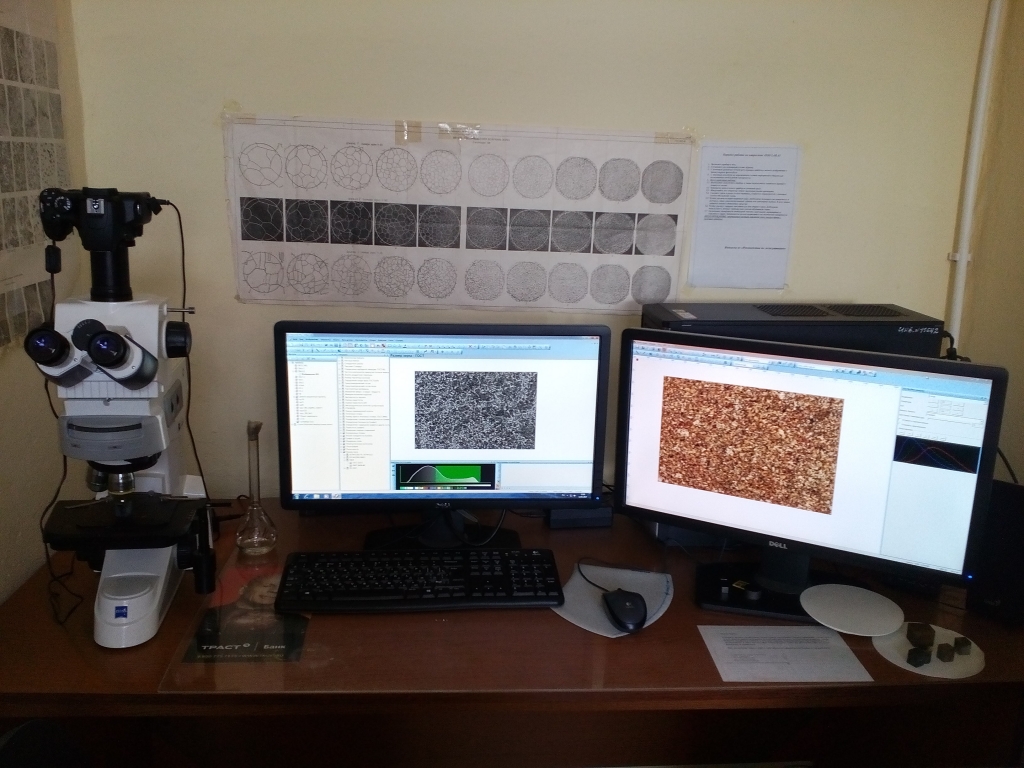

Metallographic examinations of metals and alloys, definition of their resistance to intercrystalline corrosion, are carried out by hardware-software complex Thixomet intended for monitoring microstructure of the surface, including microscope Axio Lab, the dynamic tests are effected by way of impact pendulum-type testing machine. Climatic chamber makes it possible to carry out tests of the prototypes at above-zero and subzero temperatures (-70/+180 °С), the proper preparation of samples for metallography is ensured by grinding and polishing machine tools.

|

|

|

| Complex for microstructure analysis | Climatic chamber | Polishing machine tool |

Spectral laboratory is equipped by modern optical emission spectrometers «FOUNDRY- MASTER», «ARGON-5SF» which determine chemical composition by elements with high level of accuracy: from 0,0001% up to 35 % content of elements and gases in the steels and cast irons; non-ferrous, aluminum and titanium alloys.

|

|

| Optical emission spectrometer «FOUNDRY- MASTER» | Optical emission spectrometer «ARGON-5SF» |

Laboratory for analysis of petroleum products and paint-and-lacquer materials carries out tests of paint-and-lacquer coatings and anticorrosive materials, and finished coatings on their base, rubber mixtures and articles made of rubber, polyamides, petroleum products, testbench liquids and so on. The laboratory is equipped with modern equipment for carrying out tests on adhesion property of coatings «Еlcometer-108», impact strength, coating inspection by using the method of Bresle «Еlcometer-138» and so on.

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851