| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

Innovations

Innovations have always played an important role in production development. And high competition on the pump market only heightened their role.

HMS Livgidromash has always paid great attention to implementing innovations in production, so with over 50 years of expertise we have achieved leading positions in the pump industry.

Pump engineering bureau (founded in 1959) has generated regular innovations and later on evolved into Lyvni branch of National R&D Institute of hydraulic engineering and eventually one of the R&D centers of HMS Group.

The close long-term tandem between manufacturing and scientific and technical centre has allowed to reach considerable results:

- Extensive range of pumps (over 300 types) engineered

- More than 200 highly qualified and experienced specialists to handle customer needs

- Modern experimental research base and test laboratories

- Numerous amount of research with results in copyright and patens, at the moment 20 patents

- Large contribution to applied science, over 130 scientific works such as Screw pumps and Rotary cycloidal gear pumps books; 7 GOST standards and 100 pump specifications

- High reputation confirmed by numerous awards

Own scientific and technical centre has provided for «HMS Livgidromash» strong competitive advantages, and for our clients - pumping equipment according to any operational demands.

Entering of «HMS Livgidromash» into Group HMS in 2003 considerably strengthened innovative activity by new investments into research and development. Scientific and technological centre of «HMS Livgidromash» had an opportunity to co-operate productive with other research and design organizations of the Group. All these factors have allowed taking part in large complex projects of Group HMS in oil and gas branch, atomic and thermal power engineering, housing and communal services.

Today "HMS Livgidromash" successfully continues to carry out innovative activity in its basic areas:

- Product development

- Product upgrade

- Design engineering innovations

- Process engineering

- Development of documentation and author's support of orders according to individual demands

Product development

HMS Control L3 and HMS Control ST panels. In 2011 we introduced HMS Control L3 and HMS Control ST , new protection and control panels. New controller developed by our R&D center provides precision paramenter measurement, easy setup and intuitive display. Use of modern components from leading world manufacturers guarantees reliable trouble-free operation during all operational period. Direct and soft starts are available. HMS Control L3 and HMS Control ST panels. In 2011 we introduced HMS Control L3 and HMS Control ST , new protection and control panels. New controller developed by our R&D center provides precision paramenter measurement, easy setup and intuitive display. Use of modern components from leading world manufacturers guarantees reliable trouble-free operation during all operational period. Direct and soft starts are available. |

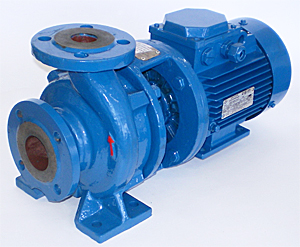

KM overhung pumps. New generation of overhung pumps for water & utilities have been engineered. KM overhung pumps. New generation of overhung pumps for water & utilities have been engineered. Due to unification of main dimensions KM pumps are completely interchangeable with analogues from other producers. Optimized flow parts decreased energy consumption in all performance range. |

Pumps for nuclear power. HMS Livgidromash actively invests into R&D for nuclear energy. Pumps for nuclear power. HMS Livgidromash actively invests into R&D for nuclear energy. Nowadays pumps for NPP include: gear pumps (AS-SH, AS-NMSH, SH, NMSH, NMSHF); three-screw pumps (3V, АS-3V); peripheral pumps (AS-VK, AS-VKS, VK, VKS); centrifugal pumps (1D, TZNA), including 2 and 3 safety class. Our pumps successfully operates in many NPP in Russia and abroad |

N1Vg 14/80 and N1Vg 170/36 multiphase progressing cavity horizontal pumps. These new types have been engineered according to increased customer requirements for operating parameters (head/capacity) and reliability for handling pure oil and products and with water, gas and solid particle content. N1Vg 14/80 and N1Vg 170/36 multiphase progressing cavity horizontal pumps. These new types have been engineered according to increased customer requirements for operating parameters (head/capacity) and reliability for handling pure oil and products and with water, gas and solid particle content. |

Product upgrade

|

Based on 1К and SM pumps HMS Group can manufacture DNA diesel pumping units based on other pumps at the customer request. Instead of the radial bearing the set of two radial thrust bearings has been used to increase reliability and axial load resistance. |

D, 1D double-suction pumps. New casting and processing increased operating parameters of D, 1D double-suction pumps, their energy efficiency and competitiveness. New material selection extended the scope of application – handling chemically active liquids, waste water with solid particle and oil product content. D, 1D double-suction pumps. New casting and processing increased operating parameters of D, 1D double-suction pumps, their energy efficiency and competitiveness. New material selection extended the scope of application – handling chemically active liquids, waste water with solid particle and oil product content. |

A6 2VV 125/40 multiphase pumps. Use of double (instead of single) mechanical seals increased their consumer features and reliability. A6 2VV 125/40 multiphase pumps. Use of double (instead of single) mechanical seals increased their consumer features and reliability. |

Design engineering innovations

|

Our developers use modern CAD, PDM, ERP, CFD systems, etc. to reduce period of design engineering, minimize errors before the prototype manufacturing and make design engineering as much flexible as possible for the customized solutions as well as embed into unified information environment of HMS Group. |

Process engineering

|

More info about process innovation you can find at Production. |

Development of documentation and author's support of orders according to individual demands

We always strive to meet customer needs and develop client oriented products. We carry this on and willing to implement customized solutions such as pump manufacturing for NPP, pumps for Vankor field, etc. We always strive to meet customer needs and develop client oriented products. We carry this on and willing to implement customized solutions such as pump manufacturing for NPP, pumps for Vankor field, etc.

|

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851

At the present stage HMS Livgidromash integrates in engineering and processes.

At the present stage HMS Livgidromash integrates in engineering and processes.

We use 3D-printer for 3D prototyping, this allows us to produce 3D flow part models: impellers, diffusers, test them, check out their geometry and minimize manufacturing errors. 3D prototyping reduced period and cost of design engineering and production preparation.

We use 3D-printer for 3D prototyping, this allows us to produce 3D flow part models: impellers, diffusers, test them, check out their geometry and minimize manufacturing errors. 3D prototyping reduced period and cost of design engineering and production preparation.