| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

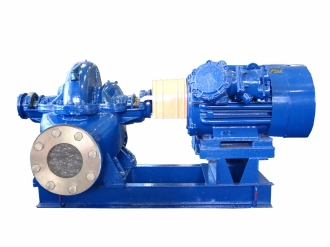

Centrifugal double-suction pumps NDs, NDv

- Series description

- Technical characteristics

- Downloads

- Related content

- Double-suction

- Chemical processing

- Midstream

- Downstream and petrochemistry

- Chemically active

- rock-oil

- masut

- oil

- benzine

- kerosin

- diesel fuel

- water + petroleum products

Function

Double-suction centrifugal pumps for handling petroleum products and electric pump units on their base are designed to pump uncontaminated petroleum products and water having admixtures of petroleum products. The content of solid inclusions in the fluids being handled is not to exceed 0,2% by mass and the size of the particle is not to exceed 0,2 mm.

Pumps are repairable items of aspect 1 as per GOST 27.003-90.

Pumps and pumping units have been designed with due account for the safety standards specified by GOST R 52743-2007.

Pumps (units) are admitted to handle liquids of IIА, IIВ categories and Т1, Т2, Т3, Т4 explosibility groups as per GOST R 51330.19. It is admitted to instal electric pumps in explosion hazard zones of class V-Iа, V-Ib, V-Ig, v-IIА according to classification in Regulations for the Design and Construction of Electrical Installations .

Design

The unit consists of the pump and driving motor which are mounted on the common baseplate and connected with elastic coupling.

The pump – is a horizontal double-suction centrifugal pump with semi-volute supply of the liquid to the impeller and with volute discharge. The operating concept of the pump consists in transformation of mechanical energy of the drive into hydraulic power of the liquid.

The pump case is a steel or cast iron casting and has a joint in the horizontal plane passing through the rotor axis. The suction and discharge branch pipes of the pump are positioned in the lower half of the case owing to which the pump may be disassembled without disconnecting the pipelines and without dismantling the motor. The case cover extends the configuration of the case ducts.

In the top portion of the case cover there is a hole М16х1,5 closed by plug for connecting a vacuum pump or linking up a vacuum building system.

The sense of rotation of the pump rotor is counter-clockwise (left-handed), as viewed from the drive end. At the Customer's request, the RH model (with right-handed rotation) of the pump may be manufactured.

Impeller – is of a double-entry type, thus, basically, it allows placing axial thrusts in equilibrium. The residual axial thrusts are taken up by the radial thrust double-row bearing. Arranged on the impeller are guard rings.

To prevent leakage of liquid over the shaft, provision is made in the pump for the end-face seals (single end-face seals with an auxiliary cuff or double end-face seals).

Application

- handling of ethyl gasolines, unleaded gasoline, orthoxylol , straight-run gasoline, fuel oil, vacuum gasoil, and also summer, winter and arctic diesel fuel in oil processing

- gas and condensate processing plants for handling of commercial oil, gasoline fractions, stable condensate, water with traces of oil products

- petrochemical companies for handling of crude, off-test oil, oil

- oil terminals for transfer of motor gasolines, diesel and aviation fuel, aviation kerosenes

- systems of operational and long-term storage of oil products

Features /Advantages

- reliable operation at down to -40 °С ambient temperature

- double suction impeller absorbs axial thrust to lower bearing load

- axial split casing provides maintenance without pipeline dismantling

Technical parameters

| Pump models | Flow (nomin.), m³/h | Head, m | Pump power input (max.), kW | Rotation speed, rpm | Rotation speed, c˜¹ | Impeller diameter, mm |

| 6NDv-Bt | 320 | 50 | 68 | 1450 | 24.2 | 405 |

| 6NDv-Bt-a | 300 | 44 | 60 | 1450 | 24.2 | 380 |

| 6NDv-Bt-b | 275 | 39 | 52 | 1450 | 24.2 | 360 |

| 8NDv-Nm | 630 | 90 | 230 | 1450 | 24.2 | 525 |

| 8NDv-Nm-a | 470 | 33.5 | 70 | 960 | 16 | 500 |

| 8NDv-Nm-b | 500 | 74 | 165 | 1450 | 24.2 | 470 |

| 8NDv-Nm | 500 | 38 | 78 | 960 | 16 | 525 |

| 8NDv-Nm-a | 550 | 82 | 190 | 1450 | 24.2 | 500 |

| 8NDv-Nm-b | 420 | 30 | 52 | 960 | 16 | 470 |

| 12NDs-Nm | 800 | 28 | 85 | 960 | 16 | 460 |

| 12NDs-Nm-a | 1150 | 56 | 220 | 1450 | 24.2 | 430 |

| 12NDs-Nm-b | 1050 | 48 | 190 | 1450 | 24.2 | 400 |

| 12NDs-Nm | 1250 | 65 | 290 | 1450 | 24.2 | 460 |

| 12NDs-Nm-a | 750 | 24.5 | 72 | 960 | 16 | 430 |

| 12NDs-Nm-b | 700 | 20.5 | 60 | 960 | 16 | 400 |

| 14NDs-Н-a | 950 | 35 | 136 | 960 | 16 | 510 |

| 14NDs-N-b | 900 | 31 | 120 | 960 | 16 | 480 |

Pump type key

Example: 6NDv-Btd-Е -b U2 TU3631-066-05747979-96 , where :

- 6 (8; 12; 14) - the diameter of the delivery branch pipe, mm, reduced by 25 times;

- NDv - the double-entry high lift pump; NDs - the double-entry mean lift pump;

- B - purpose index:B - benzine, N - oil, Nm – main oil;

- t – type of shaft seal: t - is the single end-face seal with an auxiliary one, td- double end-face seal;

- Е – case material index : Е - steel case, without index - cast iron case

- а - impeller turning index : а - is the first turning of the impeller (impeller diameter of 380mm);,

- b - second turning of the impeller (impeller diameter of 360mm)

- U2 – climatic version and location category.

Instruction manual :

All technical documentation in the Russian version of the site »

Certificates, permits :

All certificates, permits in the Russian version of the site »

Order forms :

-

Download

(19.07.2013 / 54.5 Kb / doc)

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851