| Sale of pumps: | sbyt@hms-livgidromash.ru |

|

Reception: |

lgm@hms-livgidromash.ru |

- Homepage

- About company

- Products

- Pumps by TYPE

- Pumps by APPLICATION

- Water and utilities

- Oil and Gas

- Thermal power

- Nuclear power

- Chemical processing

- Shipbuilding

- Metallurgy, mining

- Food industry

- Firefighting

- Household

- Pumps by PUMPED FLUIDS

- Pumping EQUIPMENT

- Sales

- Service

- Press center

latest news :29.11.19

- Contacts

Boosta 25-1 - Centrifugal multistage vertical Boosta pumps

- Series description

- Technical characteristics

- Downloads

- Related content

- Multistage

- Water supply

- Circulation

- Boiler water

- Water supply

- Water supply

- Circulation

- Boiler water

- Clear water

- Hot water

Function

Centrifugal multistage vertical pumps of Boosta type are intended for pumping pure water without content of abrasive inclusions, solid particles and fibrous admixtures, as well as moderate aggressive liquids, demineralized water, mixtures of water and glycol and other liquid media at a temperature ranging from -30°С up to + 120°С, which are similar in physicochemical properties and in level of impact onto the structural members of the pumps, made of chrome-nickel stainless steel.

Primary use of Boosta pumps – automated pressure boost plants which are intended for automatic boosting and maintaining the pressure within water-supply systems.

Design

The said pumps are centrifugal, multistage, vertical machines having flanged connection with a drive which is essentially a standard asynchronous motor corresponding to CENELEC norms.

All metal parts which come in contact with pumped liquid are made of stainless steel 08Х18Н10 or 08Х17Н13М2 according to the pump version.

Pumps of Boosta type are not designed to handle explosion-hazard fluids.

Application

- Industrial, municipal and rural water-delivery

- Irrigation systems and water application in agriculture

- Water treatment facilities

- Delivery of feed water to the boilers

- Fire fighting systems

- Plans for pressure boost (booster pumping plant)

Features /Advantages

- Suction and delivery branch pipes are of equal diameter and are positioned "in-line".

- Stationary base members and impellers are made of chrome-nickel stainless steel.

- Low axial thrusts allow the use of standard size series of electric motors of general industrial purpose.

- The pump is furnished with end sealing of the shaft that does not require technical maintenance and do admits the replacement of the seal without dismantling the driving electric motor.

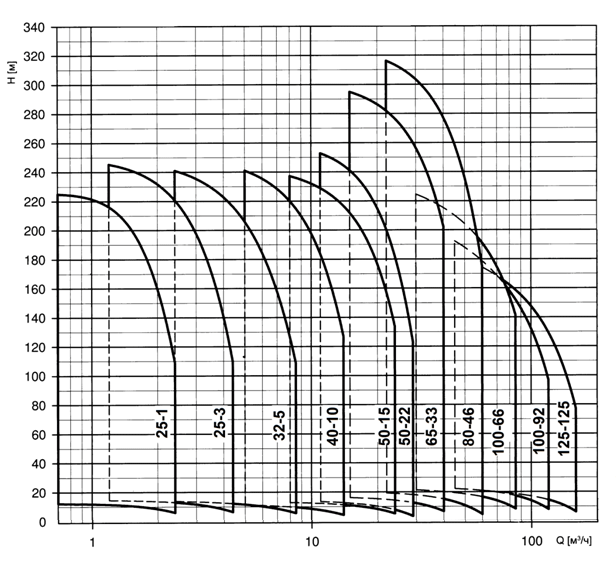

Technical parameters

| Options | Values |

| Series | Boosta |

| Flow at the point of maximum efficiency, m³/h | 1.7 |

| Head (rang), m | 6,0÷224,9 |

| Rotation speed, rpm | 2900 |

Pump type key

For Boosta pumps 25-1, 25-3, 32-5, 40-10, 50-15, 50-22 :

For example: Boosta 32 - 5 10 - F - 011 - M - Е Q1 B E , where :

- Boosta - is the trade denomination

- 32 – is the nominal (conventional) diameter of the branch pipe (DN);

- 5 - is the rated capacity (m3/h);

- 10– is the number of impellers;

- F – is the version (material, nominal (conventional) pressure and type of connection):

F = Steel 08Х18Н10, circular flanges (PN 25)

T = Steel 08Х18Н10, oval flanges (futbol) (PN 16)

R = Steel 08Х18Н10, delivery branch pipe is located above over the suction branch pipe, circular flanges (PN 25)

N = Steel 08Х18Н10, circular flanges (PN 25)

V = Steel 08Х17Н13М2, coupling connection of Victaulic type (PN 25)

P = Steel 08Х17Н13М2, coupling connection of Victaulic type (PN 40)

C = Steel 08Х17Н13М2, coupling connection of Clamp DIN 32676 (PN25)

K = Steel 08Х17Н13М2, threaded couplings as per DIN 11851 (PN25); - 011 - denotes completeness with motor :

011 = nominal power of the completed motor (кW х 10); - M - mains voltage :

Empty = three phases (380 V) – standard version

М = single phase (220 V) ; - E – is the material of elastomers (packing rings) of the pump :

E = EPDM (ethylene-propylene-diene rubber)

V = FPM (fluoroelastomer)

T = PTFE (polytetrafluorethylene) ; - Q1 - is the material of moving ring of the end-face seal:

Q1= denotes the silicon carbide; - B - is the material of the stationary ring of the end-face seal:

Q1= denotes the silicon carbide;

B = denotes the carbon-graphite impregnated with synthetic resin;

С = denotes special graphite impregnated with synthetic resin; - E - is the material of elastomers (packing rings) of the end-face seal:

E = EPDM (ethylene-propylene-diene rubber)

V = FPM (fluoroelastomer)

T = PTFE (polytetrafluorethylene);

For Boosta pumps 65-33, 80-46, 100-66, 100-92, 125-125 :

For example: Boosta 125 - 125 8/2А - G - 550 - M - Е Q1 B E , where :

- Boosta - is the trade denomination

- 125 – is the nominal (conventional) diameter of the branch pipe (DN);

- 125 - is the rated capacity (m3/h);

- 8/2А – is the number of impellers

8/2А = 8 impellers, 2 of which are reduced impellers - А ; - G – is the version (material, nominal (conventional) pressure and type of connection):

G = Steel 08Х18Н10/ cast iron, circular flanges;

N = Steel 08Х17Н13М2, circular flanges;

P = Steel 08Х17Н13М2, circular flanges (PN 40) ; - 550 - denotes completeness with motor:

55= nominal power of the completed motor (кW х 10); - M - mains voltage :

Empty = three phases (380 V) – standard version

М = single phase (220 V) ; - E – is the material of elastomers (packing rings) of the pump :

E = EPDM (ethylene-propylene-diene rubber)

V = FPM (fluoroelastomer)

T = PTFE (polytetrafluorethylene) ; - Q1 - is the material of moving ring of the end-face seal:

Q1= denotes the silicon carbide; - B - is the material of the stationary ring of the end-face seal:

Q1= denotes the silicon carbide;

B = denotes the carbon-graphite impregnated with synthetic resin;

С = denotes special graphite impregnated with synthetic resin; - E - is the material of elastomers (packing rings) of the end-face seal:

E = EPDM (ethylene-propylene-diene rubber)

V = FPM (fluoroelastomer)

T = PTFE (polytetrafluorethylene);

Instruction manual :

All technical documentation in the Russian version of the site »

Certificates, permits :

All certificates, permits in the Russian version of the site »

© Copyright 1999-2020. All rights reserved. When using materials from the site and permit the direct hyperlink on www.hms-livgidromash.com reserved.

231, Mira Street, Livny town, Orel region, Russian Federation, 303851